Polished Substrates Production Process

See OHARA’s state of the art, double sided polishing process here.

Lapping

Using a double-sided lapping machine, the material is processed to the correct thickness before polishing.

Edging and Chamfering

The outer circumference of the material is processed with a CNC device. Chamfers, orientation flats, notches, and more are also processed.

Polishing

Using a double-sided polishing machine, the parts are polished and finished. OHARA’s Super Polished Substrates have the best surface roughness and flatness values.

Clean Room & Scrubbing

OHARA operates using a Class 100 cleanroom.

Ultrasonic Cleaning

A final cleaning is performed using a 16 bath Megasonic Cleaning Unit which uses ultrasonic and ultrapure water. The drying cycle is completed with IPA vapor.

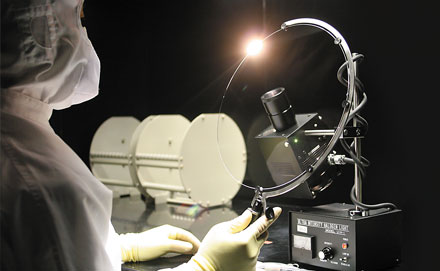

Visual Inspection

After cleaning, all wafers are visually inspected to ensure there are no defects. Packing is also completed here.

Inspection (ex. Tropel Flat Master)

Finally, sample measurements are taken prior to shipping. The outer diameter, thickness, flatness, etc. are all thoroughly measured.

Typically, the sample piece used for measurement is not shipped as a product.