3. Thermal Properties

Thermal properties are essential to processing optical glass for annealing, heat treatment and coating. We have listed the strain point, annealing point, softening point, transformation point, yield point and thermal conductivity. The linear coefficient of thermal expansion is given for two temperature ranges.

3.1 Strain Point StP

The strain point corresponds to the lowest temperature in the annealing range at which viscous flow of glass will not occur. Viscosity of the glass is 1014.5 dPa s { poise } at this temperature. The strain point is measured by the Fiber EIongation Method prescribed in JIS-R3103 and ASTM-C336.

3.2 Annealing Point (AP)

The annealing point corresponds to the maximum temperature in the annealing range at which the internal strain of glass will be substantially eliminated. Viscosity of the glass is 1013 dPa · s { poise } at this temperature. The annealing point is measured by the Fiber EIongation Method prescribed in ASTM-C336.

3.3 Softening Point (SP)

T he softening point is the temperature at which glass deforms under its own weight. Viscosity of the glass is 107.65 dPa s { poise } at this temperature. The softening point is measured by the Fiber EIongation Method prescribed in JIS-R3104 and ASTM-C338. 6

3.4 Transformation Temperature (Tg) and Yield Point (At)

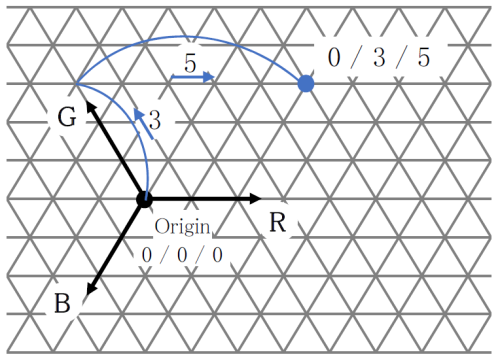

The transformation region is that temperature range in which a glass gradually transforms from its solid state into a “plastic” state. This region of transformation is defined as the transformation temperature (Tg). The transformation temperature can be determined from the thermal expansion curve

(Fig. 1). Viscosity coefficient at this temperature is approximately 1013 poise. Yield point (At) is the deformation point temperature on the thermal expansion curve, or the point at which elongation becomes zero.