Fused Silica

OHARA synthetic fused silica is produced by vapor-phase axial deposition and provides ultra-pure, bubble free material.

Fused Silica

| Method | Material | Characteristics | Application | Standard size |

|---|---|---|---|---|

| Fused Silica |

● The VAD method developed for optical fiber has been further improved to manufacture fused silica. ● Unparalleled, ideal characteristics are achieved. Ultra-high purity (total metallic impurities less than 0.5ppm) ● The OH content can be controlled to 1 ppm or less. ● High heat resistance is ensured. ● High transmission is achieved. (The SK-1310 has excellent characteristics over the entire wavelength range of ultraviolet, visible, and infrared.) ● Contains no bubbles or striae. ● Excellent laser resistance properties |

● Wafers for various types of devices such as TFT (poly-si thin-film transistor LCD), SOI (Silicon on Insulator) etc. ● Photomask substrates for ultra-LSI and LCD. ● Optical elements, lenses, mirrors and windows for ultraviolet and vacuum ultraviolet. |

[Plates] ● 50~ 500mm round ● 50~ 1000mm square |

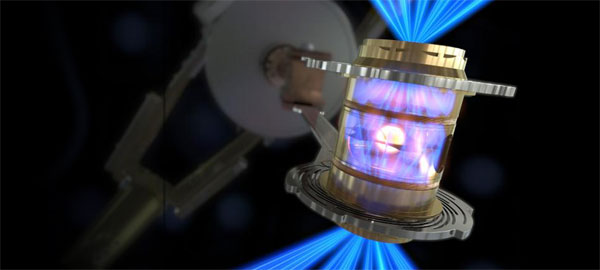

Ohara’s Optical Glass and Fused Silica in LLNL’s NIF

On October 30, 2023, the National Ignition Facility (NIF) conducted their fourth controlled fusion experiment that was able to reach scientific energy breakeven, meaning it produced more energy from fusion than the laser energy used to drive it. Read More

SK-1300 Fused Silica Series | SK1300, SK1310, SK1320