i-Line High Homogeneity Glass

Optical glass that is solarization resistant, displays excellent internal transmittance and homogeneity values and is ideal for semiconductor and astronomical optics.

i-Line High Homogeneity Glass

These 14 glass types have excellent internal transmittance in the near UV (>98% at i-line, 365 nm) and are solarization resistant. They can be produced in large sizes with outstanding homogeneity values

(+/- 0.5 x 10-6). These glasses are ideally suited for use in semiconductor (stepper cameras and illumination systems) and astronomical optics (spectrograph cameras, etc.)

| Glass Type | Internal Transmittance 10mm thick (365nm) | Solarization Resistance | Optical Homogeneity Capability Glass Type (x10-6) | Deviation of ni within a single lot (x10-5) | Tolerance of Refractive Index (x10-5) | ||

|---|---|---|---|---|---|---|---|

| Φ160mm or less | Φ210mm or less | Φ260mm or less | |||||

| S-FPL51Y | 0.997 | Good | 2.0 | – | – | ±2 | +20±20 |

| S-FSL5Y | 0.999 | Good | 1.0 | 1.6 | 2.0 | ±2 | +15±20 |

| BSL7Y | 0.998 | Good | 1.0 | 1.6 | 2.0 | ±1 | +20±20 |

| BAL15Y | 0.994 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| BAL35Y | 0.996 | Good | 1.0 | 1.6 | 2.0 | ±2 | +20±20 |

| BSM51Y | 0.995 | Good | 1.0 | 1.6 | 2.0 | ±2 | +30±20 |

| PBL1Y | 0.997 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBL6Y | 0.998 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBL25Y | 0.995 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBL26Y | 0.996 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBL35Y | 0.997 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBM2Y | 0.986 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBM8Y | 0.991 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

| PBM18Y | 0.993 | Good | 1.0 | 1.6 | 2.0 | ±2 | +10±20 |

Explanation For Table of i-Line Glass

1- Internal Transmittance

Internal transmittance of the glass is indicated as guaranteed minimum transmittance at 365nm (10 and 25 mm sample thickness). Please note this is internal transmittance, reflection losses are not included.

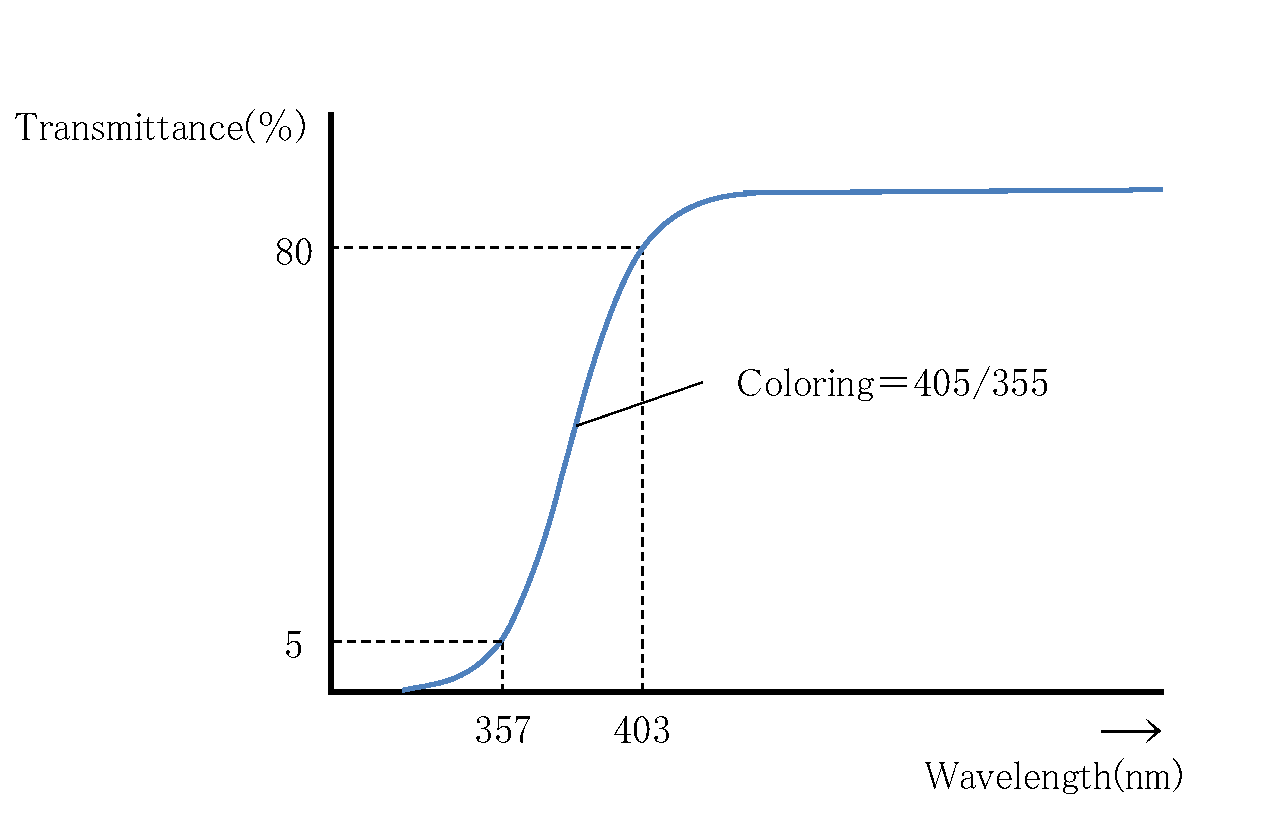

2- Solarization

The degree of solarization is indicated as a decrease in transmittance caused by radiation from a super high pressure mercury-vapor lamp. The detailed measurement method is described in the “Japanese Optical Glass Industrial Standard (JOGIS)”.

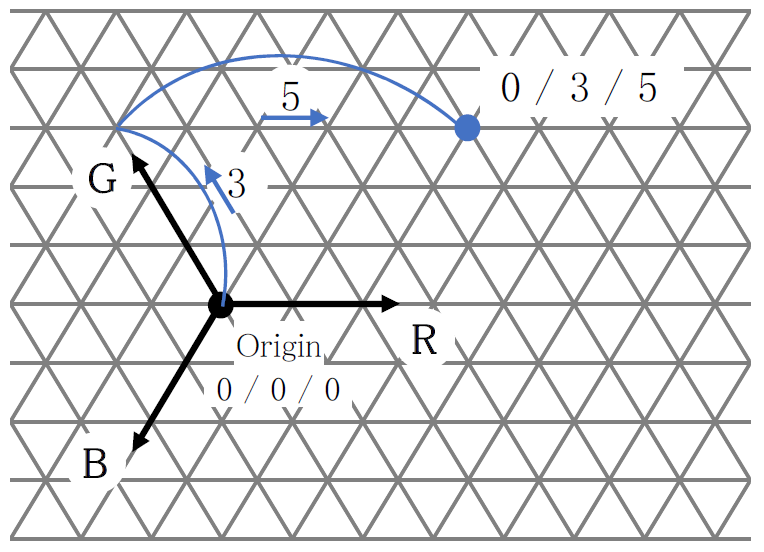

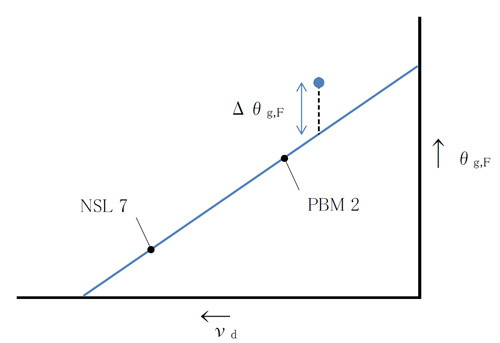

3-Optical Homogeneity

Optical Homogeneity (nΔ) is guaranteed by use of our He-Ne laser interferometers. The nΔ specification is indicated for three diameter ranges ( ∅ Ø 160 mm or less, ∅ Ø 210 mm or less, ∅ Ø 260 mm or less) due to the nΔ variances caused by glass type, size, and shape. Please note, if the ordered thickness is less than 25 mm, we will use a 25 mm thick test piece for n measurement. Please contact us when lower nΔ specifications are required.

4- Refractive Index (ni) Variation within one Lot (Sn Standard)

The indicated Sn value is the refractive index variation after annealing within a single batch (same melt, same annealing run).

5- Refractive Index Tolerance

The standard refractive index (ni) of our i-line glass is higher than our catalogue nominal values. This is due to the longer annealing times which are necessary to obtain the desired homogeneity levels. Longer annealing times result in higher refractive indices.

Example: +20±30×10-5

+20 (+0.00020) means the increase against our catalogue nominal ni value. The ±30 (±0.00030) is then the tolerance on the new nominal value. i.e. a glass type having a tolerance of +20±30 can vary from -10 (-0.00010) to +50 (+0.00050) against standard catalogue nominal. Please consult us when tighter tolerances are required.