WMS™-15

Glass-ceramic substrates enable the production of cutting edge DWDM thin-film filters.

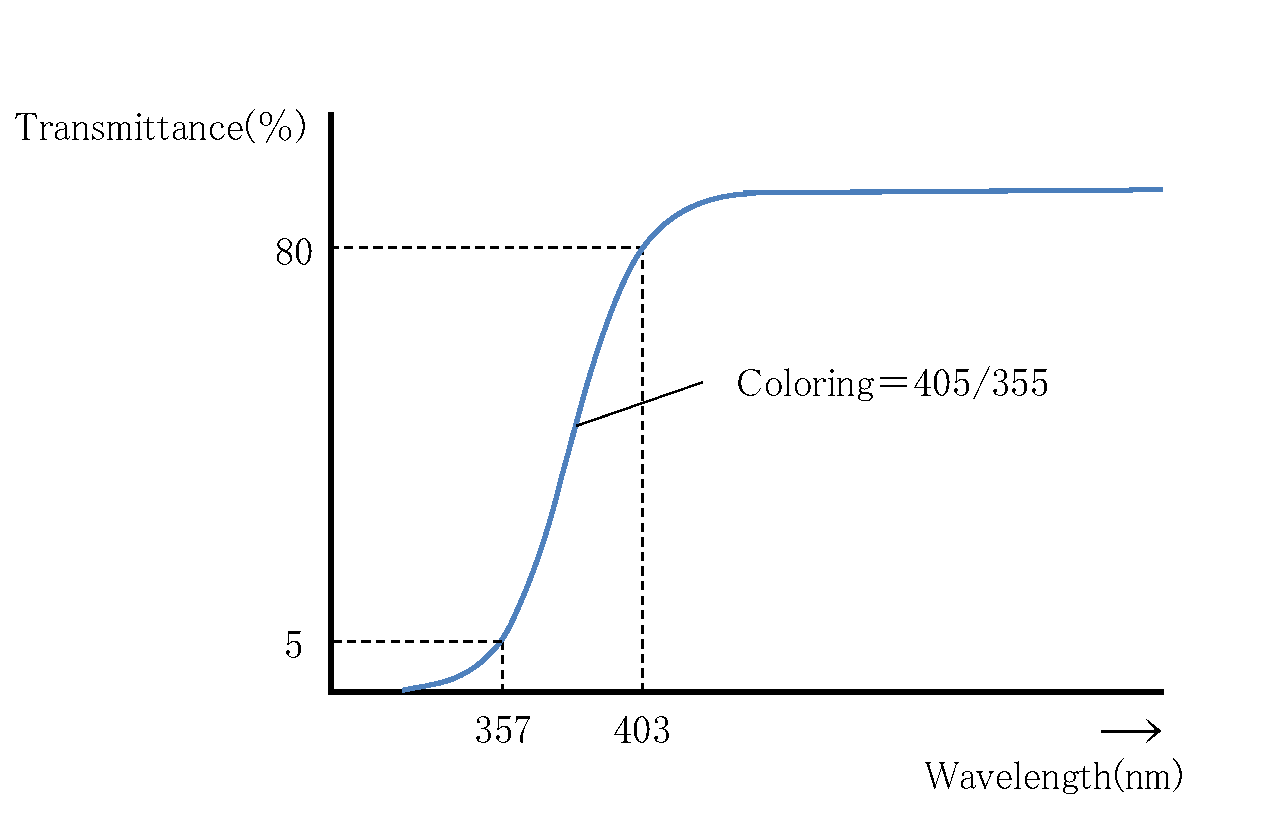

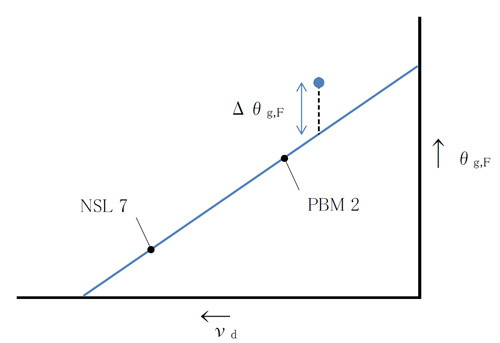

Ohara’s WMS™-15 glass-ceramic substrates will enable manufacturers to produce leading edge DWDM and thin-film filters. Our WMS™ substrates will facilitate the production of filters with extremely low thermal wavelength drift and low insertion loss values. WMS™-15 has improved internal transmittance and exceptionally low surface roughness values.

Properties of WMS™-15

| Properties | WMS-15 |

| Specific Gravity | 2.50 |

| Young’s Modulus (GPa) | Vickers Hardness |

| Thermal Conductivity (W/mK) | 1.9 |

| Heat Resistance (ºC) | 650 |

| CTE (x10-7/K) -30~+70 ºC | 114* |

| Water Resistance RW(p) | 1 |

| ATotal Alkali Content (Wt %) | 10.9 |

| Chemical Durability | Excellent |

| Int. Transmittance (%) 1550nm 1mm thick | 99.9 |

| Refractive Index 1550nm (calculated) | 1.524 |

- CTE=114 x10-7/K(-30~70°C): Standard material, Please consult us with higher CTE requirements.

- All properties are measured at room temperature except for CTE and dn/dt.

- Refractive Index and dn/dt is calculated value.

- Properties subject to change along development.

Available Products: Polished Substrate ( 1- 12inch )

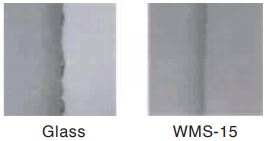

Edge Chipping Photo Pictures

The WMS-15 glass ceramic substrates are less prone to edge chipping than amorphous glass substrates.